Combined Cycle Unit Steam Attemperator Spray Turndown and Valve Reliability Improvements

Due to changing generation profiles for all power generation assets on modern grids, assets are required to cycle generation output in a frequent, often daily cycle. BEIS were engaged to redesign the high-pressure superheater and reheater steam attemperation systems on a large heat recovery steam generator primarily to achieve better turn-down, improve control valve and spray nozzle reliability and increase overall attemperator safety and plant integrity.

BEIS identified many shortcomings in the OEM design which included:

- Operation of nozzles below vapour pressure (ie flashing) of the spray water upstream of spray nozzles, causing rapid deterioration of control valve, nozzle and piping components

- Poor OEM control valve hydraulic selections

- Piping stresses exceeding the ASME B31.1 allowable stresses

- Inadequate piping supports; and

- Mechanically overloaded flow indication orifice flanges

BEIS redesigned the steam attemperation systems, including:

- Selection of new control and block valves using low-load and high-load duty parallel control valve arrangements

- Redesign of the high pressure (200 bar) spray water delivery piping system, including maintenance and operational ergonomic improvements, piping support improvements and drainage improvements

- In-house flow instrumentation redesign using flow nozzles designed to ISO5167, fully welded to eliminate future flange leakage risk

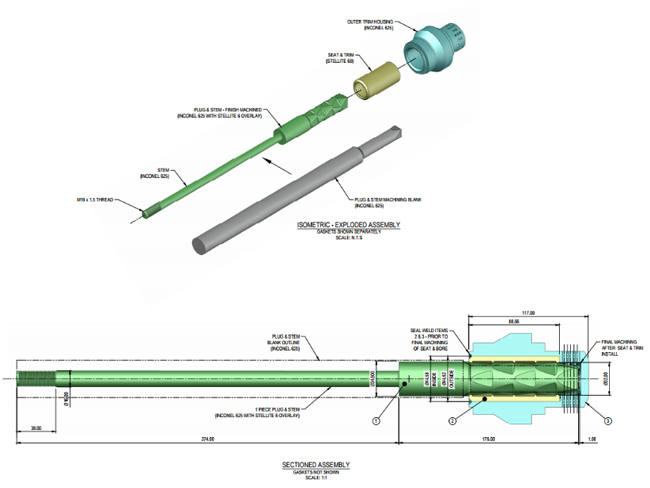

- Valve component reverse engineering and material improvements allowing the Owner to be in full control of valve component material selection, sealing surface hard facing and critical clearances. Metal style body seals were redesigned for ease of future maintenance and reduction of body seal leakage risk; and

- Detailed maintenance procedures to ensure control valves, actuators, sprays and other critical equipment is overhauled, measured, inspected and tested to a high standard

Reheat attemperator spray water piping and hanger installation

Reheat attemperator spray water low and high load duty control valve installation

Installation of new reheat steam attemperator spray water supply piping and hangers