Bond Engineering And Inspection Services

Turbine-Driven Boiler Feed Water Pump Vibration Reduction Investigation

BEIS were requested to assist site asset specialists in troubleshooting vibrational issues on an 8MW turbine-driven, 6000RPM, multistage boiler feed water pump contained within a large conventional fossil-fired power generation plant. The vibrational issues had been reducing unit generation for a considerable period of time and a data-driven approach was required to justify a strategy of short unit outages to implement reliability improvements to the pump and drive train.

BEIS initially conducted a desktop engineering investigation aimed at identifying performance and mechanical deviations from the original pump design. This investigation included:

- Hydraulic performance assessment

- Pump assembly and clearance assessments

- Pump structural and support assessment

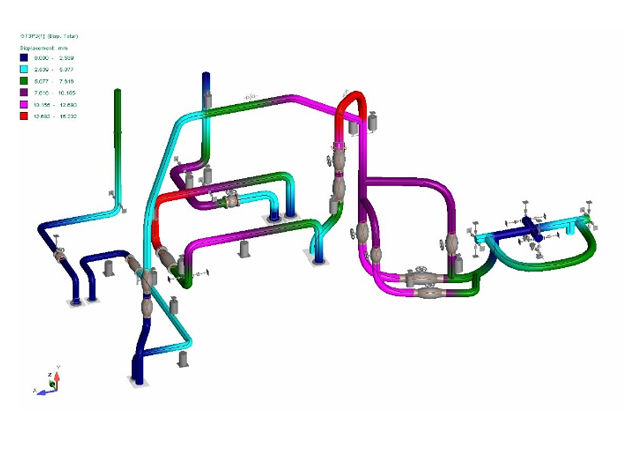

- Piping system stresses / pump nozzle loading analysis; and

- Shaft proximity monitoring instrumentation investigation

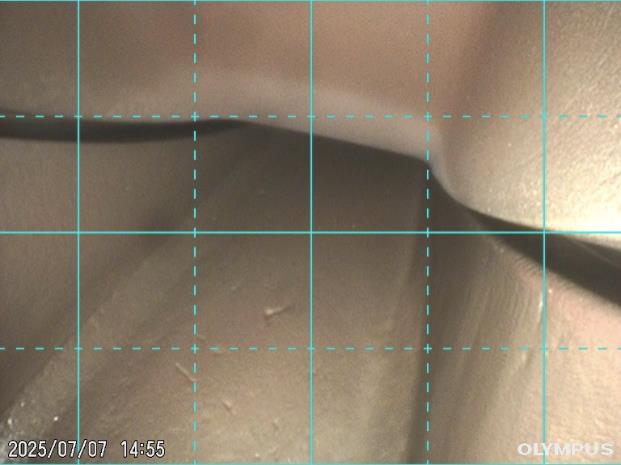

Following the desktop investigation, BEIS were able to develop and implement a remote-video inspection plan of the pump internals which identified that the impeller axial to diffuser volute positioning was outside of the design specification.

Primarily, the pump impeller axial positioning was corrected which reduced internal flow instability, reduced radial vibration and allowed the unit to operate to nameplate capacity again. By utilising the remote-video inspection plan, the need to remove the pump cassette was negated, saving the Client considerable operational downtime and maintenance resource costs. BEIS also implemented the following secondary improvements to further improve pump performance and reliability:

- Piping system support improvements and adjustments

- Pump structural support and alignment improvements

- Downstream feedwater bypass valve repairs

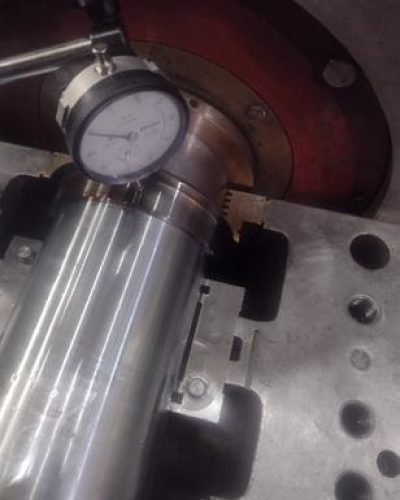

- Improved shaft proximity sensor positioning and shaft monitoring sleeves; and

- Improved future workshop assembly clearance measurement quality documents

Integrated proximity probe monitoring and oil diffuser shrink-fit sleeve installation

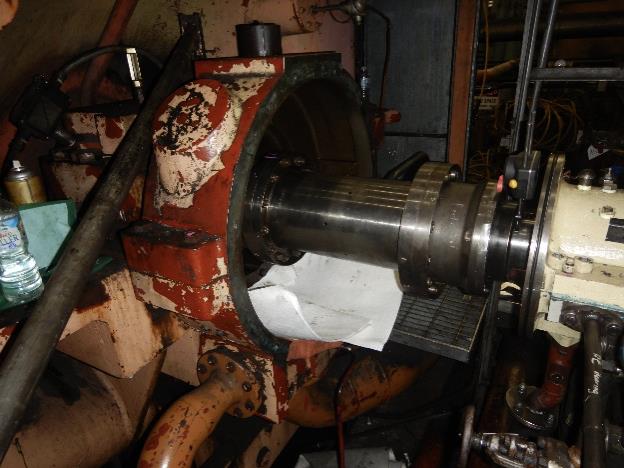

Boiler feed pump drivetrain assembly

Boiler feed pump impeller positioning remote video inspection